Product Introduction: The fundamental measure to solve the problem of substandard protein content in dairy products with the multi ring drum drying equipment produced by our company is to improve the feed structure of dairy cows - increase the proportion of alfalfa grass, which has sparked a new wave of planting alfalfa grass in China. Alfalfa grass has a high protein content, and if it is not dried in a timely manner after harvest, its moisture content can be reduced to below 14%, which is a safe moisture content and is prone to contamination and spoilage. Therefore, it is necessary to equip drying equipment for large-scale planting of alfalfa grass. The HYG series multi ring drum drying complete equipment developed by our company has received support from the Innovation Fund of the Ministry of Science and Technology, and has obtained one invention patent through technical appraisal hosted by the Shenyang Science and Technology Bureau. Its technological level has reached international advanced level, and has been promoted to more than ten provinces and cities nationwide, and exported to Spain and other countries.

Applicable materials: suitable for drying alfalfa, ginkgo leaves, Arrhenatherum elatius, sweet elephant grass, royal bamboo grass, Ageratina adenophora, Broccoli stems and leaves, mulberry twigs, ginger leaves, barley seedlings, Stevia rebaudiana and other plants.

Performance characteristics:

1. Advanced drying process

Adopting a new high-temperature fast drying process and a new structure with a three ring drum set, the drying intensity is high, and the material stays in the dryer for a short time, greatly increasing the output compared to the same volume of the dryer.

2. High degree of automation

Adopting a fuzzy control system based on letters to achieve automatic control of product quality.

3. Production safety

Equipped with automatic fire and explosion-proof devices to ensure safe operation.

4. Low drying cost

Adopting an efficient and energy-saving coal-fired hot air stove, a new high-temperature and rapid drying process, and a three ring drum set structure, the comprehensive thermal efficiency is increased by 15-18 percentage points, greatly reducing the drying cost.

5. Good quality of dry products

The moisture content of dry materials is balanced, the nutrient content is high, the color is bright, and the loss of Lutein is very small.

6. The one-time investment is 25 to 30% less than that of a neat dryer

Drying costs are 20-25% less than steam dryers

7. One machine for multiple purposes

Can dry various sheet, fibrous, and granular materials.

For example: sawdust, lees, alcohol lees, Ageratina adenophora, Broccoli stems and leaves, mulberry twigs, ginger leaves, jerusalem artichoke meal, barley seedlings, Tagetes erecta, chamomile, ginkgo leaves, corn germ, straw, Chinese herbal medicine, etc.

On site photos:

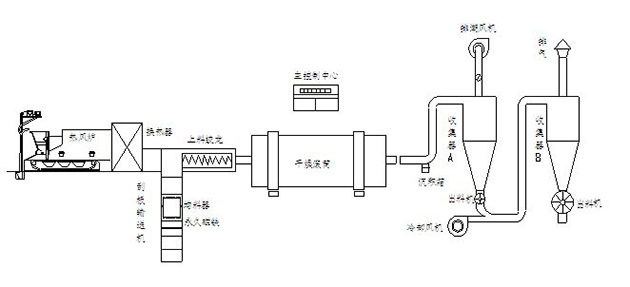

Process flow diagram:

Process flow description:

The cut fresh alfalfa grass is pushed into the feeding scraper conveyor, and the leveling machine flattens the alfalfa material layer in front of the discharge port of the scraper conveyor. The material of equal thickness enters the feeding screw conveyor, and then is discharged into the outlet of the hot air stove. It is sucked into the three ring drum dryer by the high-temperature hot air flow for drying. The dried materials are sucked into the discharge system, and the mixed stones and other debris are deposited into the sedimentation device (regularly discharged). The dry materials are separated from the air in the collector (A), and the dry materials are discharged into the cooling system through a closed air discharge machine. The cooled dry materials are discharged through a closed air discharge machine. Enter the packaging machine for packaging (or granulation, crushing, grinding, etc.). A portion of the hot air discharged from the collector is discharged into the atmosphere, and most of it returns to the heat exchanger for heating. All units are controlled by the main control center, and the system is automatically controlled by self-developed sensors, fuzzy control, and variable frequency speed regulation machines.

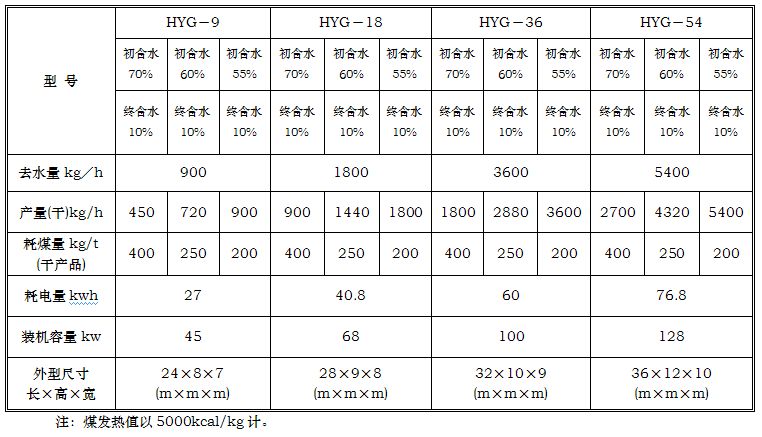

Performance Table: