一、 Working principle

Due to the excitation force generated by the two vibration motors installed on the main body, the material jumps forward along the horizontal orifice plate; The hot air passes through the orifice plate from the bottom up and passes through the material layer to achieve the purpose of dehydration and drying.

二、 Applicable scope

Suitable for drying and cooling powder materials in industries such as food, chemical, pharmaceutical, feed, plastic, salt making, grain, seed, tobacco, sugar, metallurgy, etc.

三、 Characteristics

1. Energy saving: Due to the jumping movement of materials along the orifice plate, they come into full contact with hot air, resulting in high thermal efficiency.

2. Widely used: Changing the excitation force and installation direction angle of the vibration motor can change the operating speed and motion state of materials, making it suitable for drying or cooling different materials.

3. Good drying effect: Vibration causes the material to be in a jumping state, and hot air can play a buffering role from below, resulting in low material crushing rate, less wear, and no overheating or leakage phenomenon.

4. Low noise, good vibration isolation: The equipment can be floating on the floor for work, easy to install and move, well sealed, and has a good working environment.

If a partition is added in the middle of the tank, with hot air in the front section and cold air in the rear section, both drying and cooling functions can be achieved.

6. Low investment and low operating costs. Simple structure, sturdy and durable, easy to maintain, and lightweight.

7. It can be equipped with an automatic feeding device for continuous and uniform feeding, forming an automatic flow production line.

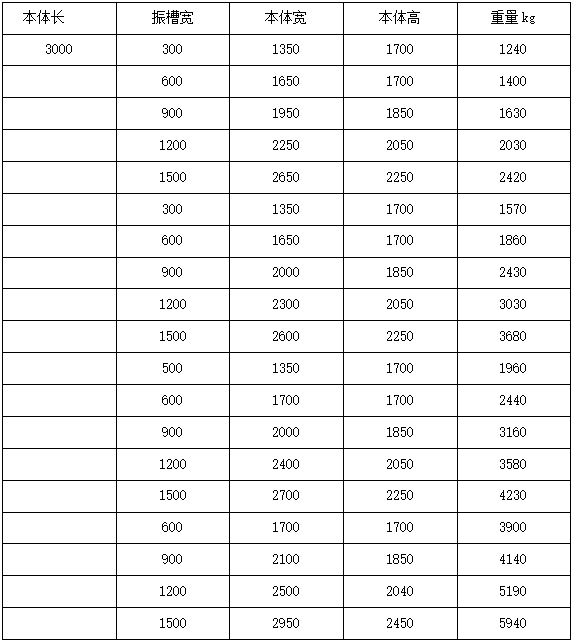

四、Main technical parameters

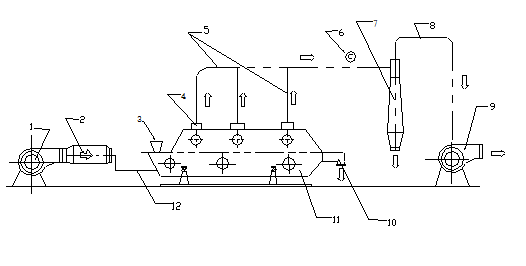

五、Structure and System Diagram

1. Structure

The structure is shown in the figure, consisting of the main body, frame, vibration isolation device, vibration motor, etc.

(1) Main body (2) Feed inlet (3) Air outlet (4) Vibration motor (5) Cleaning peep door (6) Air inlet (7) Outlet (8) Rack

2. System diagram

1. Supply fan 2, heater 3, feeder 4, hose 5, suction duct 6, temperature gauge (2 pieces) 7, dust collector 8, suction duct 9, suction fan 10, discharge port 11, dryer 12, supply duct