Product Introduction: Used for dehydration of various fiber materials. It can remove most of the moisture in the material, greatly reducing the burden on the dryer, greatly increasing the output of the dryer and reducing energy consumption. It is an essential treatment equipment for high humidity materials before drying. After dehydration, the material can directly enter the drying equipment, greatly reducing drying energy consumption.

Used for dehydration of various fiber materials, it can remove most of the moisture in the material.

Applicable materials: Used for dehydration of various fiber materials.

Performance characteristics:

This machine has a simple structure, convenient operation and maintenance, and good process performance, making it an ideal equipment for drying units.

On site photos:

Process flow description:

The screw extruder is mainly composed of components such as motor, reducer, variable diameter and pitch screw shaft, inlet and outlet box, water filter cage, etc. The working principle is that after the equipment is operating normally, the materials that need to be dehydrated are evenly added to the extruder from the feed box, and then pushed along the axial direction by the rotating blades of the screw. During the advancement process, the materials are subjected to the action of the variable diameter and pitch screw and the adjustment of the extrusion head, forming a huge extrusion pressure, which causes the materials to undergo mechanical dehydration under external force. The water is discharged from the filter cage through the sieve, and the dehydrated materials are discharged at the outlet box, Thus achieving the purpose of dehydration. The dehydrated material can be directly fed into the dryer for drying. For different types of materials, changes in yield, and parameters such as final water content, the speed of the extrusion head and extruder can be controlled by adjusting.

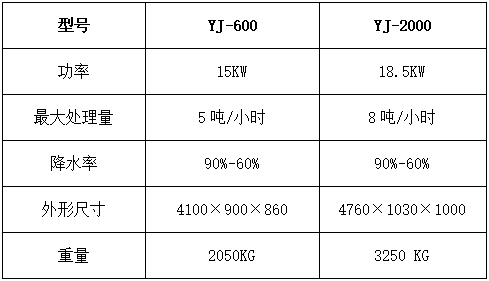

Performance Table: